Technical Ceramics

Explore Technical Ceramics

Technical Ceramics and Wear Parts: SiC Whisker Substrate Capabilities

Technical ceramics, also known as advanced ceramics or engineering ceramics, are a group of inorganic non-metallic materials with high-temperature stability, exceptional wear resistance, and superior mechanical properties. These materials are widely used in various industries, including aerospace, automotive, electronics, and medical, due to their unique combination of properties.

Wear parts, a subset of technical ceramics, are specifically designed to withstand extreme conditions such as high temperatures, corrosive environments, and abrasive wear. These components are vital for enhancing the performance and durability of industrial equipment and machinery.

SiC Reinforced Alumina Substrate Capabilities

Silicon Carbide Whisker (SiCw) reinforced alumina is a leading material in the realm of technical ceramics and wear parts, renowned for its remarkable properties and wide-ranging applications. SiCw reinforced alumina is a ceramic matrix composite (CMC). Most CMCs are very expensive and this high cost prevents their use in many applications. Such is not the case with SiCw reinforced alumina. These CMCs can be produced cost effectively yet deliver remarkable properties.

SiCw reinforced substrates offer several key advantages:

1. **Extreme Hardness and Wear Resistance**: SiCw reinforced CMCs exhibits exceptional hardness and wear resistance, making it suitable for applications where components are subjected to abrasive wear and harsh operating conditions.

2. **High Thermal Conductivity**: SiCw substrates possess high thermal conductivity, enabling efficient heat dissipation and thermal management in electronic and high-power applications.

3. **Chemical Inertness**: SiCw is chemically inert, offering excellent resistance to corrosive chemicals and harsh environments, making it an ideal choice for wear parts in chemical processing and semiconductor manufacturing.

4. **Ultra-High Loss Tangent**: SiCw is what electrical engineers call a lossy material. At RF and microwave frequencies, it has a tan delta of more than 10,000! It is ideal for radio wave and microwave absorption, EMF blocking, and RF and MW heating.

Applications of SiC Substrates

SiCw substrates find applications in a wide array of industries and products, including:

- **Industrial Machinery**: SiCw reinforced wear parts are employed in heavy-duty industrial equipment, such as pumps, valves, and bearings, where resistance to abrasion, corrosion, and high temperatures is critical for prolonged operational life.

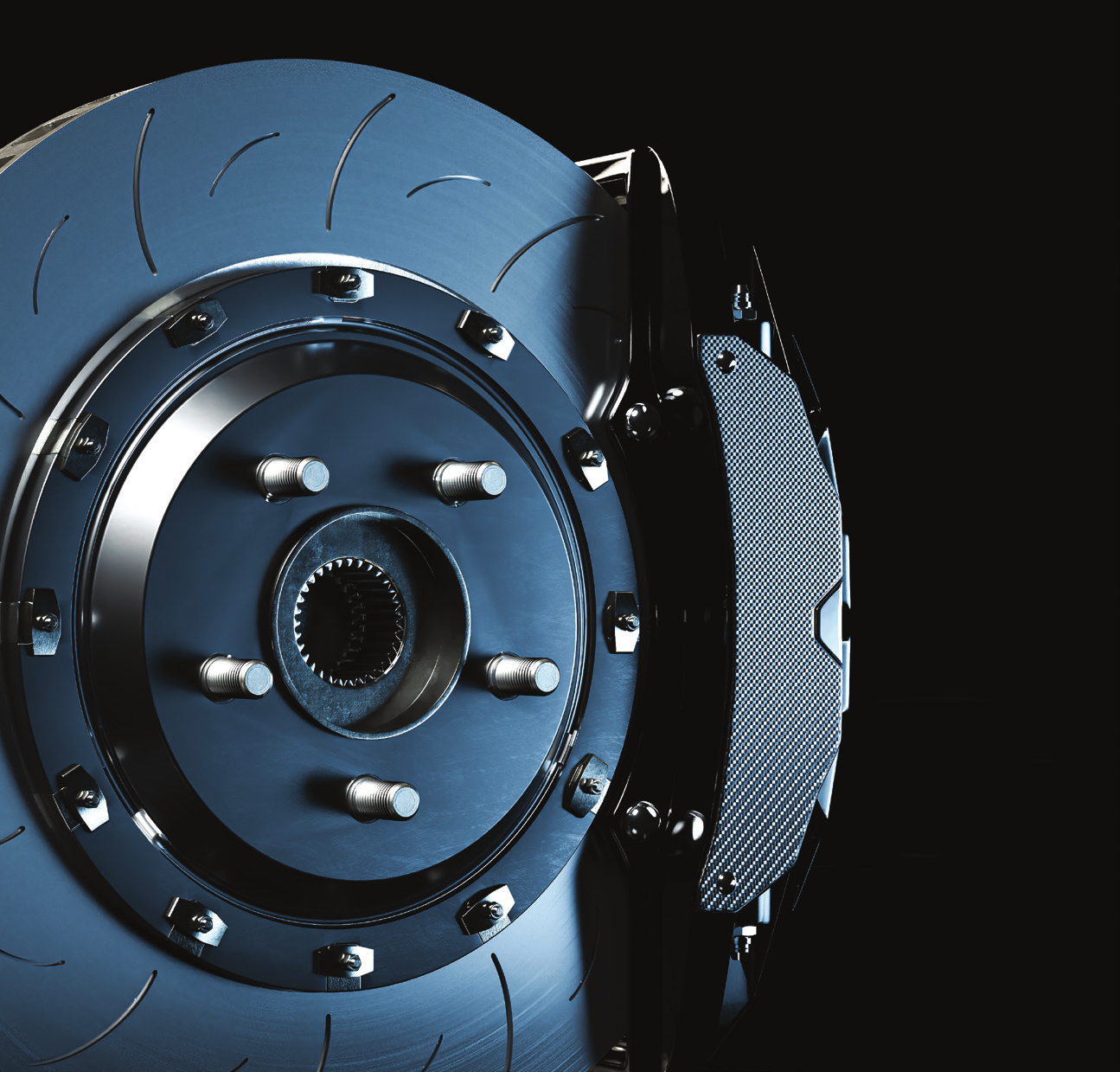

- **Automotive Sector**: SiCw reinforced components contribute to enhanced fuel efficiency and reduced emissions in automotive applications, including components for engines, exhaust systems, and brake systems.

- **Energy Sector**: SiCw reinforced substrates play a crucial role in energy-related applications, including components for solar panels, wind turbines, and nuclear energy systems due to their thermal stability and durability.

Partnering with Us for SiCw Substrate Solutions

SiCw fiber reinforced CMCs are unique. At Haydale, we specialize in the development and production of high-quality substrates and wear parts for diverse industrial applications. Our team of experts leverages cutting-edge manufacturing techniques and advanced material science to provide custom solutions that meet the unique requirements of our clients.

Whether you need SiCw substrates for industrial machinery, automotive systems, or energy-related applications, we are committed to delivering top-tier products that exceed expectations. Partner with us for your SiC substrate needs and experience the advantage of superior performance, reliability, and durability in your applications.

For inquiries or to learn more about our SiCw substrate capabilities, please contact us today.

Get a free quote

Contact Us

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.