Ceramic Powders

Explore Ceramic Powders

SI-TUFF® Silicon Carbide Whiskers (microfibers)

Haydale has the world’s largest installed capacity of silicon carbide whisker (SiCw). Sold under the SI-TUFF® brand name, SiCw diamond-like SiC microfiber used to toughen protective coatings, ceramic matrix composites, and metal matrix composites. SiCw extends service life, improves abrasion and scratch resistance, thermal conductivity, temperature stability, and hardness.

Because it is a fiber, it delivers these properties at low loading levels. In addition, due to lower surface energies, it typically residues below the surface. Therefore, it provides benefits without affecting other desirable properties, including non-stick/release, flexibility, and low friction.

SI-TUFF® SiCw comes in three versions:

SFC: raw SiC whisker. Typically used in ceramics. SFC must be milled to deagglomerate the particles and allow the discrete fibers to properly disperse in composites.

SF-1: de-agglomerated SiC whisker (microfiber). Use in coatings, metallurgical additives, ceramic matrix composites, and metal matrix composites. To make SF-1 we process SFC in a proprietary process to thoroughly de-agglomerate the product. The SiC whiskers are freed from the larger particles and are easy to disperse in the target matrix.

SF-1E: epoxy functionalized SF-1. Here we take SF-1 and graft epoxy functionality onto the surface. The product will react with amines, isocyanates, acids (and acid anhydrides), phenols, alcohols, and thiols. The microfiber then is chemically bonded into a substrate. The result is faster cure rates, and mechanical properties that are 15-30% stronger than SF-1 alone.

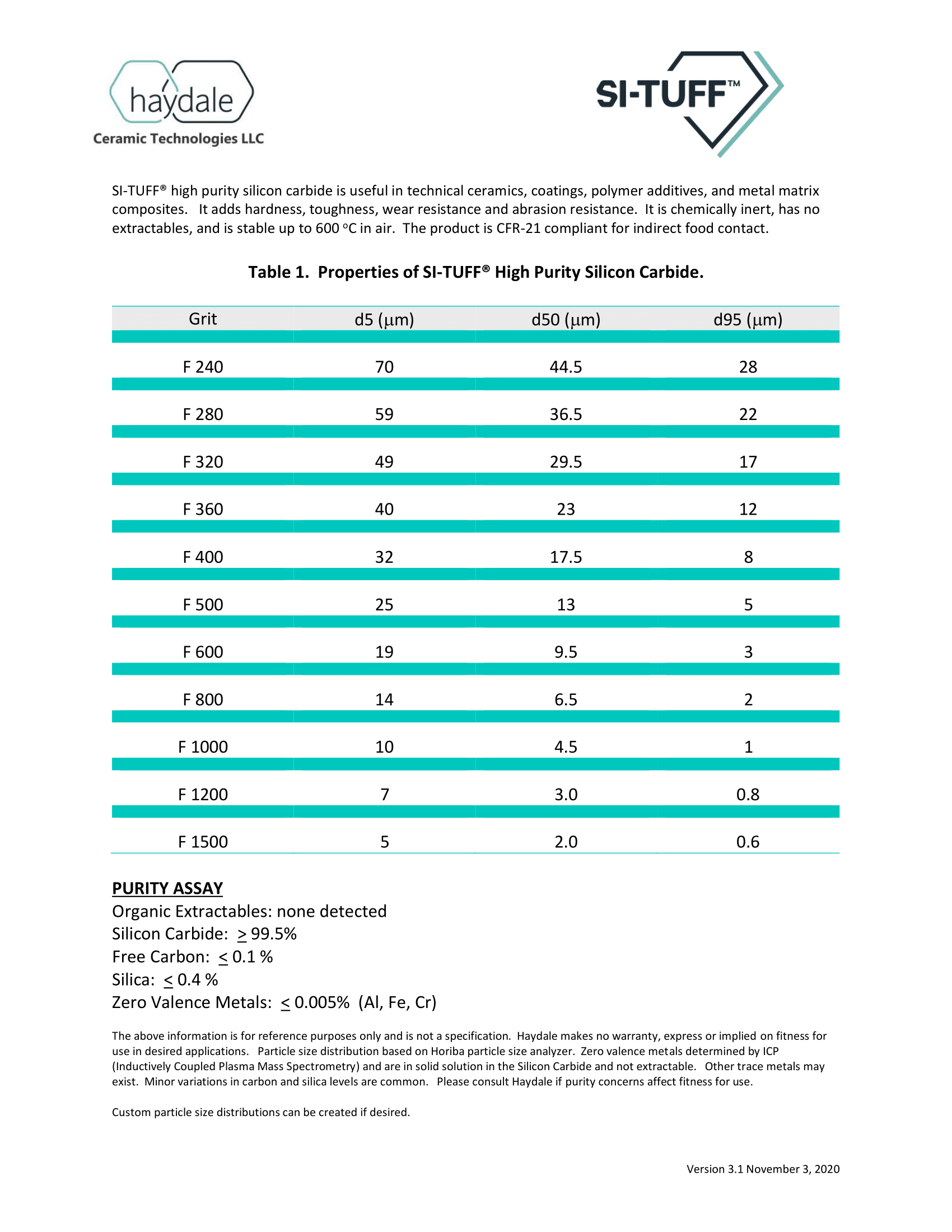

SI-TUFF® Silicon Carbide Powders

Haydale produces high purity (>99.7%) green silicon carbide. Silicon carbide powder (SiCp) has a wide range of properties:

1. Hardness: SiC is the second hardest material known, with a hardness approaching that of diamond. This property makes it highly resistant to wear, abrasion, and erosion.

2. High Service Temperatures: SiC is stable in air up to 600°C and stable in inert environments up to 2700°C

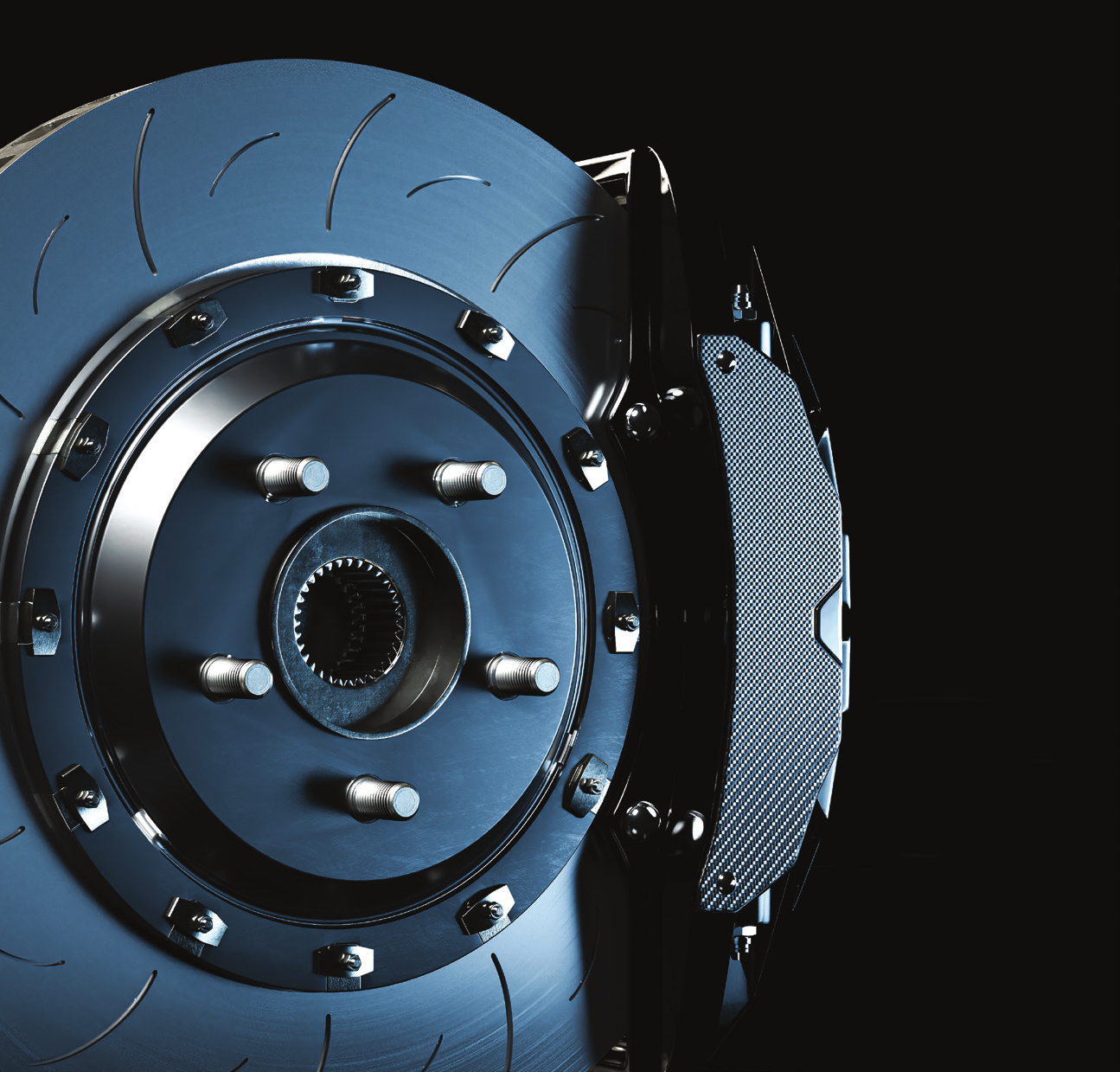

3. Chemical Inertness: SiC is chemically inert, and is resistant to chemical attack b acids, bases, and corrosive gases. This makes it useful in applications where chemical resistance is required, such as in chemical processing, electronics, and automotive industries.

4. High Strength: Silicon carbide has a high strength-to-weight ratio, making it strong and lightweight. This property makes it suitable for structural applications, including aerospace components, automotive parts, and ceramic kiln furniture.

5. Excellent Thermal Conductivity: SiC has high thermal conductivity. This property makes it useful in applications where efficient heat dissipation is required, such as in heat sinks, power electronics, and high-power devices.

Due to its exceptional Haydale silicon carbide finds applications in paints and coatings, metallurgical additives, ceramic wear parts, metal matrix composites, and abrasives.

Engineered Ceramic Blends for Cutting Tools

CT-10: CT-10 is a dry press-ready engineered blend of Si-TUFF silicon carbide microfiber (SFC) and alumina used to produce highly wear resistant ceramics. It does contain binder. It is characterized by excellent wear resistance and thermal and dimensional stability. CT-10 is completely inert and can be used in the most demanding physical and chemical environments.

Processing and Applications

For use in high performance ceramic wear parts, including:

• Dies

• Pipe liners

• Nozzles

• Other critical process equipment

CT-10 is de-binded in air or vacuum and fired in inert gas at atmospheric pressure. For applications which require the utmost fracture resistance, CT-25 should be considered.

CT-25: CT-25 is a hot-press-only engineered blend of Si-TUFF silicon carbide microfiber (SFC) and alumina used to produce the absolute toughest ceramics out there. CT-25 is binder-free. It has very high fracture toughness, and is used in the most demanding environments, including cutting tools and mission-critical applications that require utmost mechanical properties.

Get a free quote

Contact Us

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.